- Home

- Facilities listing

- Advanced composites laboratory

Advanced composites laboratory

About the advanced composites laboratory

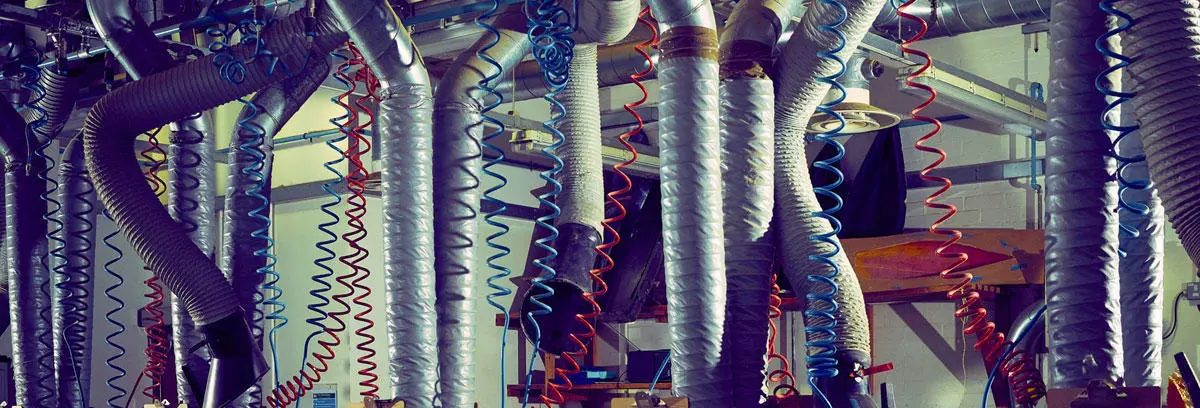

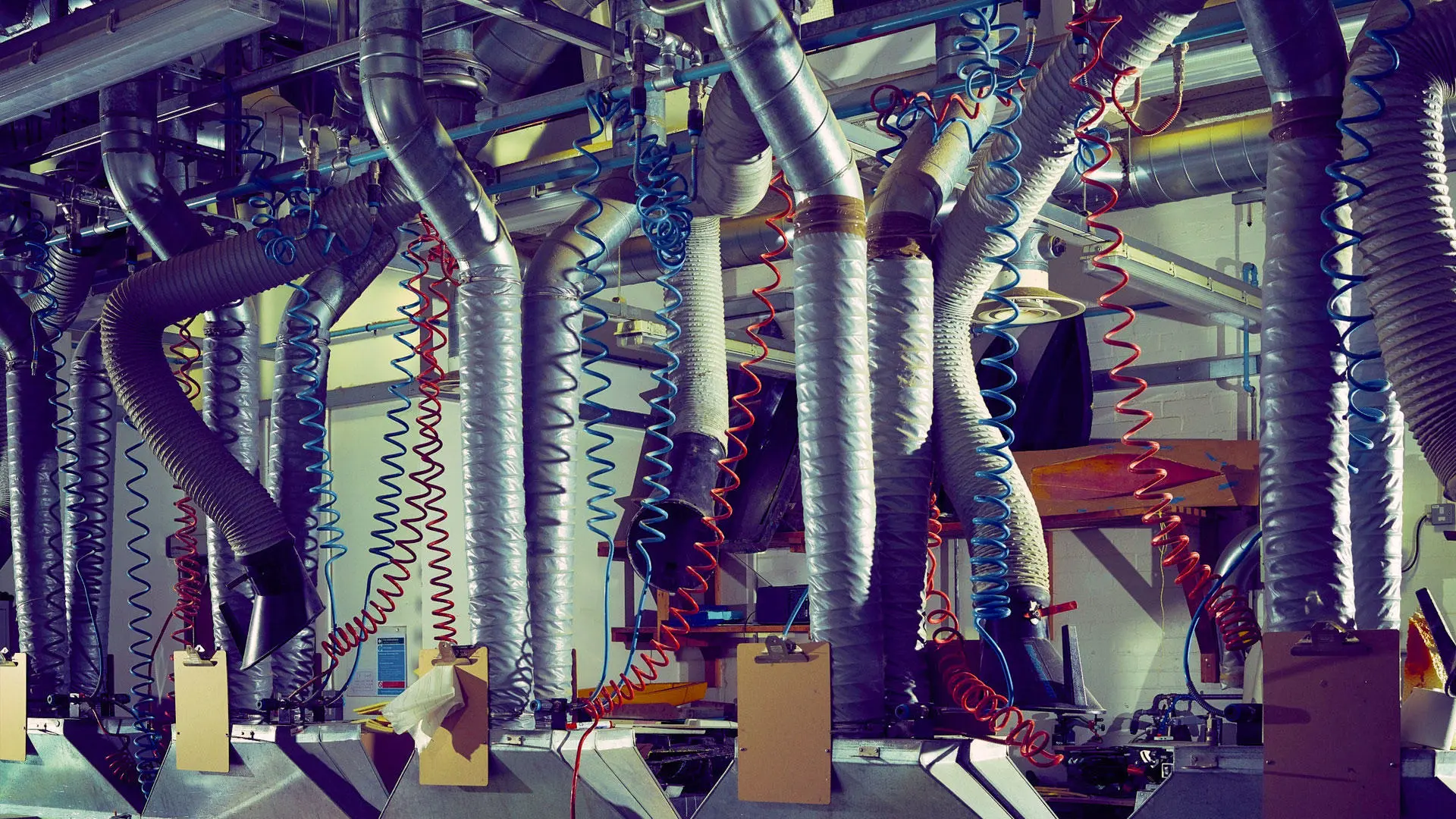

The Solent composites lab is designed to handle all of the processes commonly seen in composite construction, from hand- and vacuum-assisted laminating to pre-impregnated fibre construction and resin infusion. We also undertake the construction of prototype models, towing tank models, display models and tooling, offering a turnkey solution to model evaluation and a cradle-to-grave approach to creating a prototype or product.

Equipped to handle polyester and epoxy resin in any combination of FRP materials, including glass, carbon and aramid fibre, the composites lab has a well-established reputation in the area of marine construction and repair.

Organisations from a range of industries are beginning to explore the possibilities of using composite construction, and Solent University can provide the specialist facilities and knowledge you require. Past commissions have involved building towing tank models, test panels, surfboards, repair and improvement for sailing and rowing craft, parts for kit cars, and a range of other bespoke components.

Gallery

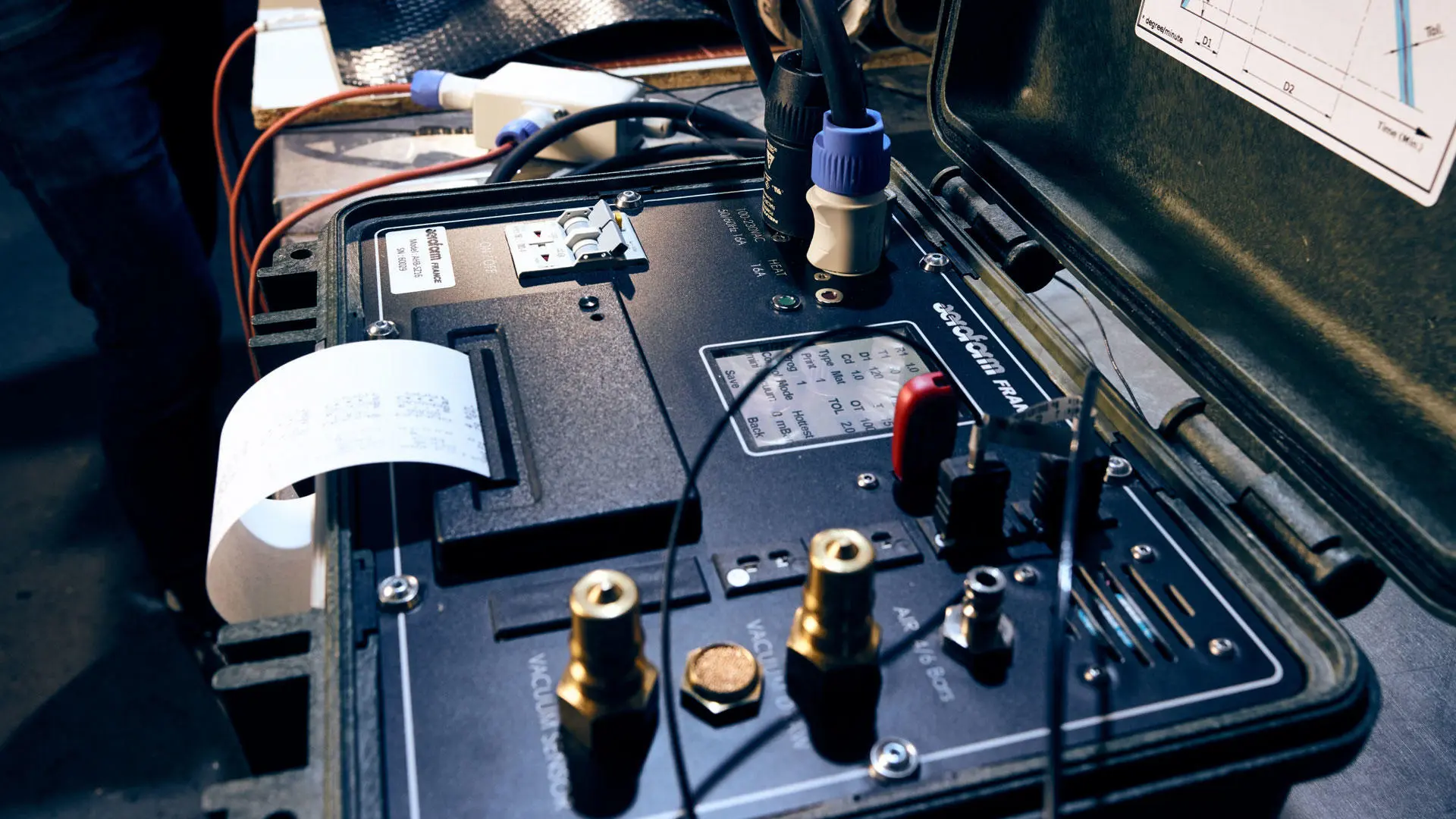

Equipment

- Twelve workstations for specialised, advanced composite building methods.

- Wet lay vacuum bagging for single project or short product run construction methods using male/female mould tools.

- Resin infusion for in-mould production using female tooling.

- Pre-impregnated fibre construction for female tooling requiring elevated temperature.

- Repair methods for each of the above.

Courses that use this facility

- BEng (Hons) Yacht and Powercraft Design

- BEng (Hons) Yacht Design and Production

- BEng (Hons) Renewable Energy Engineering

- MSc Sustainable Marine Craft and Superyacht Design